Introduction

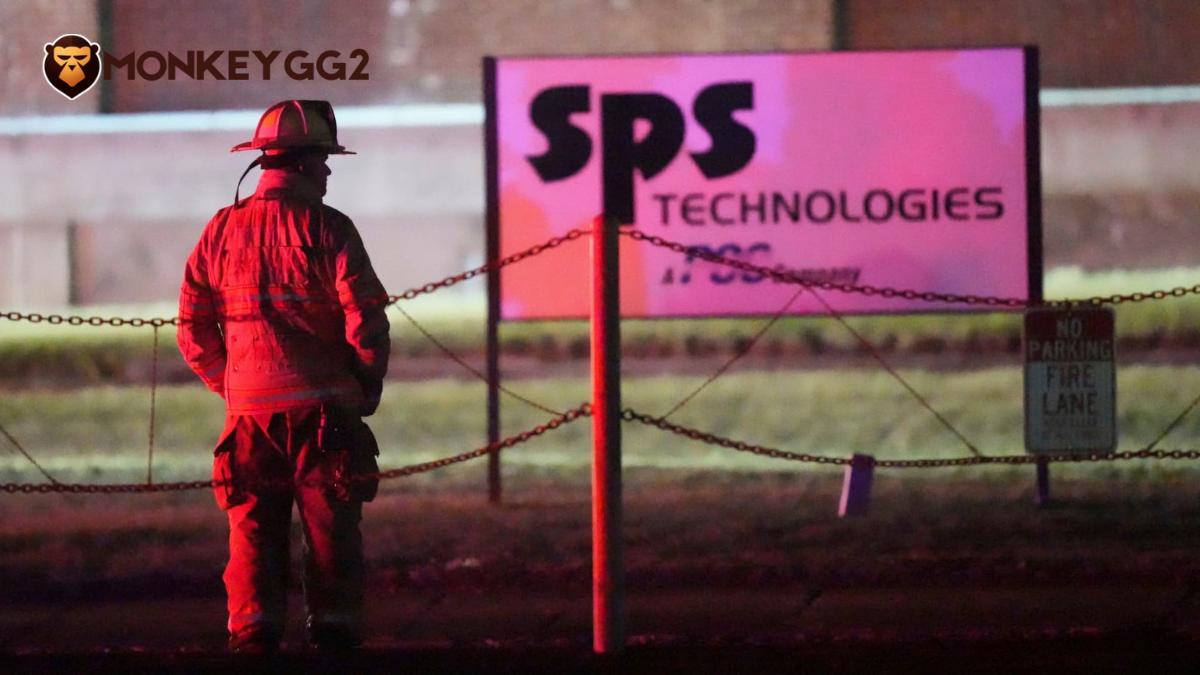

SPS Technologies is a renowned name in the fastening industry, known for producing high-performance fasteners used in critical applications. With a legacy spanning over a century, the company has set benchmarks in precision engineering, reliability, and innovation. Whether in aerospace, automotive, military, or industrial applications, SPS Technologies is synonymous with durability and strength.

Fasteners are the backbone of modern engineering, ensuring the structural integrity of everything from airplanes to industrial machinery. Given the critical nature of these applications, companies worldwide rely on trusted manufacturers like SPS Technologies for their fastening solutions. By consistently delivering high-quality products, SPS Technologies has built a strong reputation among engineers, manufacturers, and industry leaders.

History and Legacy of SPS Technologies

Founded in the early 1900s, SPS Technologies has grown from a modest fastener manufacturer to a global industry leader. The company’s journey began with a vision to create precision-engineered fastening solutions for demanding industries. Over the decades, it has expanded its product offerings, integrating cutting-edge technology and advanced manufacturing processes.

Key milestones in the company’s history include pioneering the development of high-strength aerospace fasteners, contributing to military advancements, and setting new standards in fastening technology. SPS Technologies has also played a crucial role in large-scale projects, including aircraft manufacturing, defense applications, and industrial machinery production. Today, its legacy is built upon an unwavering commitment to quality, innovation, and customer satisfaction.

Product Range and Applications

Aerospace Industry

One of the primary sectors that rely on SPS Technologies is the aerospace industry. Aircraft require fasteners that can withstand extreme conditions, including high-altitude pressure changes, temperature variations, and mechanical stress. SPS Technologies provides aerospace fasteners that meet stringent standards such as AS9100 and NAS (National Aerospace Standards). Their fasteners are used in aircraft fuselages, wings, engines, and landing gear assemblies, ensuring safety and durability.

Automotive and Transportation

SPS Technologies also serves the automotive and transportation industry, supplying fasteners designed for high-performance vehicles. Whether in commercial trucks, electric vehicles, or motorsports, their fastening solutions ensure optimal performance and structural integrity. The company offers a variety of automotive fasteners, including bolts, nuts, screws, and specialty components tailored to meet the specific needs of vehicle manufacturers.

Industrial and Manufacturing

Beyond aerospace and automotive, SPS Technologies plays a significant role in industrial manufacturing. Heavy-duty machinery, construction equipment, and energy infrastructure all require reliable fastening solutions. The company produces high-strength fasteners capable of withstanding extreme pressure, vibrations, and harsh environmental conditions. Industries such as oil and gas, renewable energy, and heavy engineering benefit from SPS Technologies’ specialized fastening products.

Military and Defense

SPS Technologies has a long-standing relationship with military and defense organizations. The company manufactures fasteners that comply with military-grade specifications, ensuring durability in high-stress environments. These fasteners are used in defense aircraft, naval vessels, armored vehicles, and missile systems. Their ability to withstand extreme conditions makes them an essential component in national defense strategies worldwide.

Innovations and Technology at SPS Technologies

Innovation is at the core of SPS Technologies’ success. The company invests heavily in research and development to create next-generation fastening solutions. Advanced materials such as titanium alloys, corrosion-resistant coatings, and heat-treated steel are integral to their product offerings.

Precision manufacturing processes, including CNC machining, cold forging, and automated assembly, ensure high-quality output. SPS Technologies also leverages digital technologies, such as AI-driven quality control systems and 3D printing for prototyping. By staying ahead of technological advancements, the company continues to set industry standards for reliability and performance.

In addition to product innovation, SPS Technologies is committed to sustainability. The company has implemented eco-friendly manufacturing practices, reducing waste and optimizing energy efficiency. By focusing on sustainable production, it aligns with global efforts to reduce the environmental impact of industrial manufacturing.

Quality Standards and Certifications

SPS Technologies adheres to the highest quality standards, ensuring that its fasteners meet and exceed industry requirements. The company holds certifications such as ISO 9001, AS9100 (for aerospace applications), and MIL-SPEC compliance (for military applications). These certifications reflect its commitment to excellence in manufacturing and product reliability.

Every fastener undergoes rigorous testing, including tensile strength evaluation, fatigue analysis, and corrosion resistance assessments. The company’s quality control processes involve advanced inspection techniques, such as non-destructive testing (NDT) and computer-aided dimensional analysis. By maintaining strict quality assurance protocols, SPS Technologies guarantees the safety and performance of its products across diverse industries.

SPS Technologies’ Global Reach

With manufacturing facilities and distribution centers worldwide, SPS Technologies has established a strong global presence. The company’s fasteners are used in North America, Europe, Asia, and beyond. It collaborates with leading aerospace manufacturers, automotive giants, and defense organizations to supply critical fastening solutions.

The company’s strategic expansion into emerging markets has further strengthened its global footprint. By investing in new production facilities and forming partnerships with international distributors, SPS Technologies ensures that its products are accessible to industries worldwide. This global reach reinforces its position as a trusted leader in fastening technology.

Why Choose SPS Technologies?

Choosing SPS Technologies means opting for reliability, precision, and innovation. The company’s fasteners are known for their superior strength, resistance to wear and tear, and compliance with industry standards. Here’s why SPS Technologies stands out:

- Unmatched Quality: Every fastener is engineered for durability and performance.

- Industry Expertise: Over a century of experience in high-performance fastening solutions.

- Customization: Ability to develop custom fasteners tailored to specific industry needs.

- Global Presence: Strong distribution network and international partnerships.

- Sustainability Commitment: Environmentally friendly manufacturing practices.

Conclusion

SPS Technologies has firmly established itself as a leader in high-performance fastening solutions. With a legacy of excellence, a commitment to innovation, and a focus on quality, the company continues to set industry benchmarks. From aerospace to defense, automotive to industrial manufacturing, SPS Technologies’ fasteners play a crucial role in ensuring structural integrity and operational safety.

As industries evolve, SPS Technologies remains at the forefront, delivering advanced fastening solutions that meet the ever-growing demands of modern engineering. Whether you need high-strength aerospace bolts or custom fasteners for industrial applications, SPS Technologies is a name you can trust.

Also Read: bard names